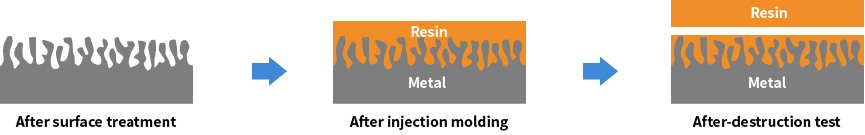

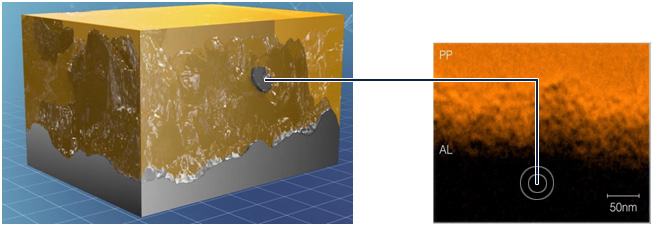

The metal and resin that have been drilled onto the surface with special technology are joined by injection molding using an anchor effect.

Business Sector

The metal and resin that have been drilled onto the surface with special technology are joined by injection molding using an anchor effect.

When observing the joint cross section using carbon mapping, it was seen that the resin (orange) infiltrated into the metal (black).

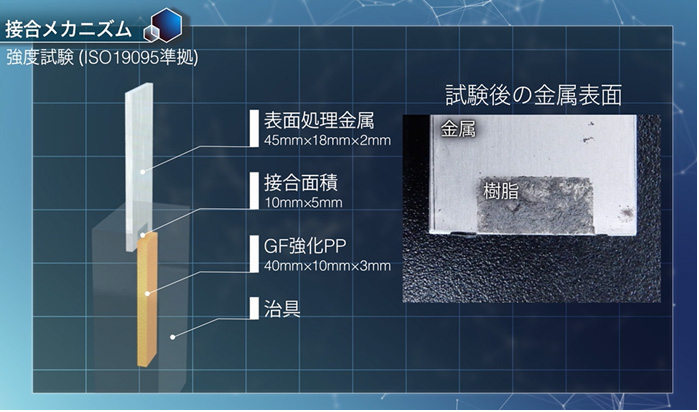

In the strength test (compression shear test), according to ISO19095, this heterogeneous material bonding technology shows how the destruction of the base material demonstrates high bonding strength.

In addition, this heterogeneous material bonding technology allows for a shear bonding strength of 20 MPa or more when conducting thermal shock tests, heat resistance tests, and constant temperature and humidity tests under severe conditions, proving the airtightness between the metal and resin bonding interface.