Business Sector

Nonferrous metal

Aluminum, a representative non-ferrous metal, is the best choice for lightening EVs, servers, and various subsidiary materials over time.

Special Material

GM80

It is an aluminum rolled material containing 8% or more magnesium.

Magnesium is a very light metal, having a specific gravity of two-thirds that of aluminum. When a large amount of magnesium is added to an aluminum alloy, the strength increases to protect the durability of a vehicle, and the weight of the vehicle body can be significantly reduced to increase fuel efficiency. In addition, since the strength of the product is comparable to that of duralumin, even without heat treatment, it can be used not only as an automobile material with high-strength properties but also as an alternative to various apparatuses, electric devices, and facilities due to its low price. Currently, Glolinx is leading the non-ferrous material development business by successfully establishing stable alloy composition and complex process technology for breakthrough quality and price, in cooperation with many companies around the world.

Magnesium is a very light metal, having a specific gravity of two-thirds that of aluminum. When a large amount of magnesium is added to an aluminum alloy, the strength increases to protect the durability of a vehicle, and the weight of the vehicle body can be significantly reduced to increase fuel efficiency. In addition, since the strength of the product is comparable to that of duralumin, even without heat treatment, it can be used not only as an automobile material with high-strength properties but also as an alternative to various apparatuses, electric devices, and facilities due to its low price. Currently, Glolinx is leading the non-ferrous material development business by successfully establishing stable alloy composition and complex process technology for breakthrough quality and price, in cooperation with many companies around the world.

Application Field

-

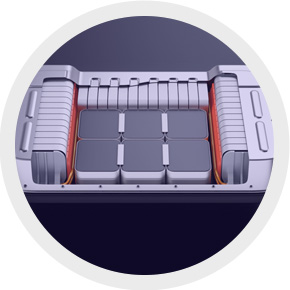

Battery pack case for electric vehicles

Battery pack case for electric vehicles -

Body frame for internal combustion engine

Body frame for internal combustion engine -

IT and mobile devices

IT and mobile devices

General Material

General aluminum materials such as 10XX, 20XX, 30XX, 40XX, 50XX, 60XX, and 70XX

Glolinx puts all effort into finding and supplying any material requested by our customers.

Glolinx puts all effort into finding and supplying any material requested by our customers.

-

Aluminum Billet

Aluminum Billet -

Extruded Material

Extruded Material -

Aluminum Slab

Aluminum Slab -

Rolled Material

Rolled Material

Characteristics of each aluminum material

| Alloy Name | Characteristic | Usage |

|---|---|---|

| 1060 | It is used as a conductor and guarantees 61% of IACS. If strength is required, use 6101. | Electric wires and bus bars |

| 1100 | An aluminum alloy for general use with a purity of 99.0% or more, which looks a little white after anodizing and has excellent moldability and corrosion resistance. | General equipment, carburetors, printing plates, building interior materials, and heat exchanger parts. |

| 2011 | A free-cutting alloy, having excellent machinability and high strength, but poor corrosion resistance. When corrosion resistance is required, 6262 alloy is used. | Volume shafts, brake pistons, optical parts, and automobile parts. |

|

2014 2017 2024 |

High copper content deteriorates the corrosion resistance but improves the strength, so it is used as a structural or forging material. | Aircraft parts, hydraulic machinery parts, defense products, and rivets. |

| 2018 2218 |

An alloy for forging, normally applied to forged parts requiring heat resistance due to its good forgeability and excellent high temperature strength. The corrosion resistance is not as high. | Cylinder heads and pistons |

| 2618 | A forging alloy with excellent high temperature strength | Pistons, rubber molds, and general heat-resistant parts. |

| 2219 | It features high strength and excellent low and high temperature properties, as well as excellent weldability. | Low temperature tanks, defense products, and aerospace equipment. |

| 3003 3203 |

Compared to 1100, it has about 10% higher strength and excellent formability, weldability, and corrosion resistance. | Copiers/print drums, marine materials, and optical parts. |

| 4032 | It has an excellent heat resistance and abrasion resistance, with a small thermal expansion coefficient. | Pistons and cylinder heads |

| 5005 | It has a similar strength to 3003 and has excellent workability, weldability, and corrosion resistance. The finish after anodization is also good. It matches 6063 in color. | Interior materials for construction, and interior materials for vehicles and ships. |

| 5052 | A typical alloy with medium strength, with excellent corrosion resistance, weldability, and formability. In particular, it has high fatigue strength compared to its strength, and has excellent seawater resistance. | General plates, ship materials, vehicles, building materials, can ends, honeycombs. |

| 5056 | It has excellent corrosion resistance, good cutting processability, and excellent anodic oxidation treatment and coloring performance. | Camera lens barrels and communication device parts. |

| 5083 | A welding structural alloy with the highest strength among non-heat treated alloy, good seawater resistance and low temperature characteristics. | Ship parts Vehicle parts, low temperature tanks, pressure vessels. |

| 5086 | An alloy for non-heat treated welding structures, with higher strength and better seawater resistance than 5154. | Ships, pressure vessels, and magnetic disks |

| 5154 | It has about 20% higher strength than 5052, and other characteristics are similar to 5052. | General plates, ship materials, vehicles, building materials, can ends, honeycombs, Pressure vessels |

| 6005 | Due to T5 treatment, the strength is similar to 6061. It is used for products that require relatively high strength while having a complex shape. | Railway vehicles, vehicle parts, and general machine structural materials. |

| 6061 | A heat-treated, corrosion-resistant alloy, with considerably higher durability obtained from T6 treatment. | Ships, vehicles, land structures, machine parts, forging materials, and mold materials. |

| 6063 | An extruded alloy, with excellent extrudability, to enable it to easily form a complex cross section, and with good corrosion resistance and surface treatment performance. | Building material (sashes), guard rails, vehicles, furniture, home appliances, ornaments |

| 6082 | It is similar to 6061 in terms of properties but about 10% higher than 6061 in strength. | Ships, vehicles, land structures, and machine parts. |

| 6101 | A strong and high conductive material. 55% IACS is guaranteed. | Electric wires and bus bars |

| 6151 | It has excellent forging processability, and good corrosion resistance and surface treatment. It is normally applied in forged products with complex shapes. | Machinery and auto parts |

| 6262 | A free-cutting alloy and has better corrosion resistance than 2011. It has the same strength as 6061. | Camera lens barrels, carburetor parts, brake parts, and gas equipment parts. |

| 6N01 | It has a mean strength value of 6063 and 6061. | Vehicles, land structures, and ship's stores. |

| 7003 | A welding structural extruded alloy. Although it is little weaker than 7N01, it can make large items with small thickness due to its good extrudability. Other properties are similar to those of 7N01. | Vehicle parts, motorcycle rims, and wheelchair parts. |

| 7050 | An alloy with quenching performance improved, from 7075, with good stress corrosion resistance. It is used for thick plates and forged products. | Aircraft parts and high-speed rotating body. |

| 7075 | It is one of the highest strength among aluminum alloys, but has poor corrosion resistance. The corrosion resistance can be improved by cladding with 7072, but the cost is high. | Aircrafts, defense parts, machine parts, ski sticks, and mold materials |

| 7N01 | A welding structural alloy, with high strength. The strength of the weld is restored to the same level as that of the base metal by leaving it at room temperature. The corrosion resistance is also quite high. | Vehicles and motorcycle rims |

TOP